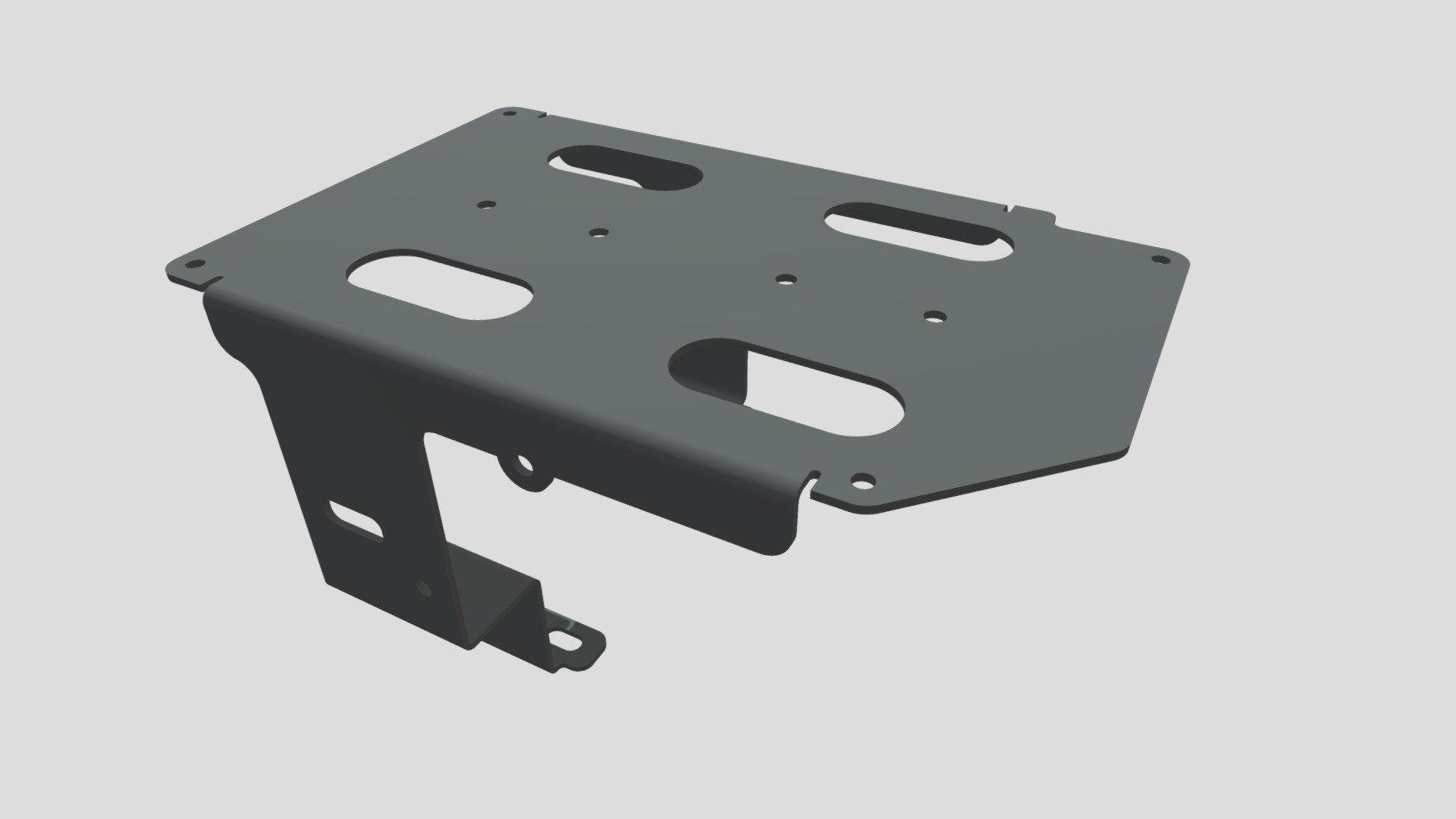

1/0 wire, 300 AMP little fuse and 500 AMP winch solenoid disconnect ran to in cab switch to turn power on to the winch..Good info, thanks. Tell us about your winch. Have you used it much? How does it perform under load? Do you have a fuse at the battery? If so what size? Wire size you ran to the front?

Warn EVO 8S max current draw of 298 Amps according to Warn. Ran it up a 15% incline to properly spool the rope but otherwise haven’t needed it yet. Checked for heat in the wiring and winch and there was nothing that could be felt to the touch after the long constant pull.

I went with smaller winch for weight and reduced amp draw and will use two snatch blocks depending upon the situation to get up to 24,000lbs. Pulling power while only putting 8k on the winch and 16k on the bumper if absolutely necessary.